Quality

The quality is at par with any brands in the state. We assure that the physical properties like Yield & Tensile strengths, minimum 15% elongation is within the range specified by BIS. The most important quality issue in TMT bars is widely known as the CV (Characteristic value) of bars. This particular test will prove the quality of the bar. VIRLA GOLD 550 is one such premium quality bar to maintain CV as designated by BIS.

Our 5S INSPECTION SYSTEM

To deliver a uniform TMT bar throughout, any company should maintain a BIS and ISO advisable quality and inspection system, alon with their necessary laboratory instruments. At Virla, we have developed a 3 Stage quality inspection system, which starts from -

- Raw Material Inspection : Every consignment is thoroughly chemically and physically inspected before transferring into yards. We are equipped with advanced spectrometer to check the chemical properties of the billets.

- Rolling Section : To ensure the flawless and uninterrputed production cycle, we regularly monitor the running temperature of the billets. Our stands and rolls are also regularly QC on periodic cycle to avoid inferior quality production.

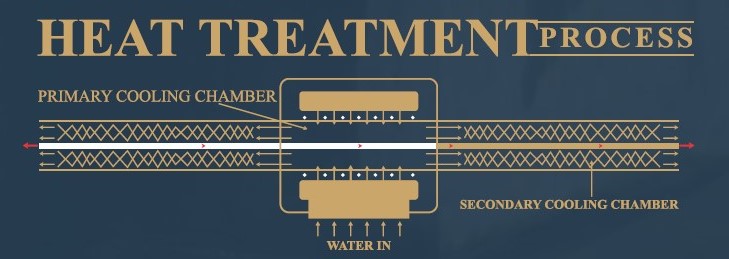

- TMT Inspection : As our primary Motto to deliver quality TMT bars, our every batch is tested in between the process as well as final product to ensure uniform quality